-

In 1983, the center established a laboratory management system according to ISO / IEC guideline 25 (later revised document No. ISO / IEC 17025). In December 1984, the center passed laboratory accreditation and Shanghai metrology certification (later called qualification accreditation), and passed the examination and acceptance and metrological certification (later called qualification accreditation) by the former State Bureau of Technical Supervision in March 1990. The categories of testing products include: wires and cables for electrical equipment, power cables and accessories, bare wires and products, overhead insulated cables, optical fiber cables, communication cables, winding wires, wire components, electrical accessories and raw materials for wires, cables and optical cables.

The industries involved include: transmission and distribution, traditional and new energy power generation, petrochemical, construction, transportation, aviation, military products, etc.

The standards involved include: national standards, relevant industry standards, IEC standards, regional standards (HD, en, etc.), standards of major developed countries (UL, ASTM, VDE, BS, as, San, etc.).

Main customers include: State Grid, China Southern Power Grid, provincial / municipal quality and Technical Supervision Bureau, China Quality Certification Center, China Classification Society, TUV rhein, DEKRA, Kema, UL, etc.

-

In 2004, the center established the inspection organization management system according to the requirements of ISO / iec17020. In 2005, the center was recognized by China National Accreditation Committee for conformity assessment (CNAs), and became the first organization to carry out inspection business in the field of domestic wire and cable industry.

At present, the inspection business mainly includes: factory supervision of wires and cables, quality assessment of wires and cables and their accessories, accident analysis, completion acceptance of wires and cables and their accessories, and status assessment.

n terms of inspection, participated in many major projects in China. Typical cases include: Supervision and manufacture of 500kV single core self contained oil filled submarine cable body for the second circuit interconnection project between China Southern Power Grid and Hainan power grid; supervision and manufacture supervision of 500kV conductor for Three Gorges power transmission and transformation project of State Grid; supervision and inspection of 750kV expanded diameter conductor of northwest power grid; installation supervision of Expo high-voltage cable; installation supervision of 110kV power cable of Shanghai electric power; assessment of cable sheath cracking accident of Daya Bay nuclear power station; CNOOC JZ20-2 gas mine SW to MUQ platform 10kV fault submarine cable technical identification; CNOOC JZ21-1 platform 35kV fault submarine cable technical appraisal; Zhejiang Shengsi 50kV paper insulation DC cable fault analysis.

-

The testing center of special testing equipment for wires and cables in mechanical industry and the 22nd measuring and testing center station of mechanical industry (hereinafter referred to as the center) are authorized calibration and testing institutions independent of the development, manufacture and trade of wire and cable special test equipment approved by relevant national departments.

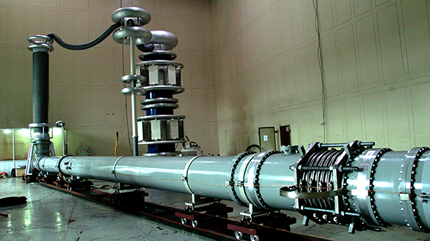

As early as June 1986, the center passed the metrological certification of the former Shanghai Municipal Bureau of Metrology and the former National Bureau of Metrology in July of the same year. It can calibrate and test rubber and plastic insulated wire and cable test equipment, winding wire test equipment, high voltage cable test equipment, etc.

It provides calibration services for more than 800 wire and cable enterprises and more than 20 related testing institutions every year. At the same time, it also formulates the calibration methods and standards of special test equipment for wires and cables, and carries out the training for calibration personnel of special test equipment in the wire and cable industry.

-

In order to master the inspection and detection ability of the certified inspection and testing institutions, strengthen the management of wire and cable testing laboratories, ensure and improve the detection ability and level of relevant laboratories, and ensure the scientificity and accuracy of the test results. Every year, the center will cooperate with the relevant quality supervision departments of various regions or countries to organize and carry out capacity verification activities among different laboratories. The qualification of the center in this respect meets the requirements of ISO / IEC 17043 "competence of providers of proficiency testing program", which was approved by CNAs for the first time on September 25, 2013. The test items for each capability verification are different according to the requirements of relevant quality supervision organizations. The main items carried out include cable structure size, conductor DC resistance, insulation resistance, high temperature pressure of materials, tensile properties of materials, etc. the reference test methods are mainly GB / T 2951-2008 general test methods for insulating and sheathing materials of cables and optical cables, GB / t3048-2007 test methods for electrical properties of wires and cables.

-

The testing center of special testing equipment for wires and cables in mechanical industry and the 22nd measuring and testing center station of mechanical industry (hereinafter referred to as the center) are authorized calibration and testing institutions independent of the development, manufacture and trade of wire and cable special test equipment approved by relevant national departments.

As early as June 1986, the center passed the metrological certification of the former Shanghai Municipal Bureau of Metrology and the former National Bureau of Metrology in July of the same year. It can calibrate and test rubber and plastic insulated wire and cable test equipment, winding wire test equipment, high voltage cable test equipment, etc.

It provides calibration services for more than 800 wire and cable enterprises and more than 20 related testing institutions every year. At the same time, it also formulates the calibration methods and standards of special test equipment for wires and cables, and carries out the training for calibration personnel of special test equipment in the wire and cable industry.